As the demands of the modern supply chain evolve, many businesses face the challenge of accommodating different pallet types due to their regional or international operations. Managing UK and Euro pallets together requires careful planning, efficient space utilization, and proper handling procedures.

In this article, we will guide you through the process of efficiently handling both UK and Euro pallets, ensuring seamless warehouse operations and improved productivity. So, whether you’re a warehouse manager or a logistics professional seeking practical solutions for managing diverse pallet types, this post is for you. Let’s dive in and explore the strategies and techniques that will help you effectively manage UK and Euro pallets in a single warehouse.

Understanding UK and Euro Pallets

To effectively manage UK and Euro pallets in one warehouse, it’s crucial to have a solid understanding of the characteristics and dimensions of each pallet type. Let’s take a closer look at UK and Euro pallets, their specifications, and the key differences between them.

Explanation of UK Pallets and Their Dimensions

UK pallets, also known as “Standard 1200” or “CHEP” pallets, are widely used in the United Kingdom and other parts of the world. These pallets have dimensions of 1200mm x 1000mm, making them slightly larger than Euro pallets.

Overview of Euro Pallets and Their Standard Size

Euro pallets, also known as “EUR” pallets, are commonly used throughout Europe. These pallets adhere to the European Pallet Association (EPAL) standards and have dimensions of 1200mm x 800mm. Euro pallets are known for their sturdy construction and standardized dimensions, facilitating compatibility across different European countries.

Key Differences Between the Two Types

While both UK and Euro pallets serve the same fundamental purpose of safely transporting goods, there are significant differences to consider when managing them together in one warehouse.

- Dimensions: UK pallets are larger, measuring 1200mm x 1000mm, compared to the 1200mm x 800mm dimensions of Euro pallets. This variation affects how you plan your storage space and configure your racks to accommodate both pallet types efficiently.

- Load Capacity: UK pallets generally have a higher load capacity compared to Euro pallets due to their larger size, but it’s imperative you check the type of pallet build as this directly impacts load capacity. It’s also crucial to consider weight restrictions and ensure your storage systems can handle the load capacity of both pallet types.

- Compatibility: Euro pallets are more prevalent in Europe, while UK pallets are commonly used in the UK and other regions. When managing both pallet types, it’s essential to ensure compatibility with handling equipment, such as forklifts, pallet jacks, and conveyors.

Evaluating Warehouse Space and Layout

To successfully manage UK and Euro pallets in one warehouse, it’s essential to evaluate your available space and optimize the layout to accommodate both pallet types efficiently. Let’s explore some key strategies for evaluating and maximizing your warehouse space.

Assessing Available Warehouse Space for Pallet Storage

Begin by assessing your warehouse space to determine how much area you have available for pallet storage. Consider factors such as the total floor space, ceiling height, and any existing storage systems or infrastructure.

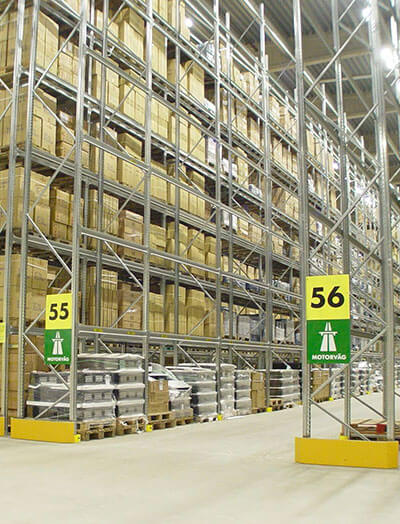

Evaluate the space in terms of both square footage and cubic footage. Remember, effective space utilization involves utilizing the vertical space as well. This evaluation will provide a baseline understanding of your warehouse’s capacity to handle both UK and Euro pallets.

Optimising Racking and Shelving Systems for Dual Pallet Types

Choosing the right racking system is crucial for efficient pallet storage. Consider the following options to accommodate both UK and Euro pallets:

- Adjustable Pallet Racking: Invest in adjustable pallet racking systems that allow for flexible configurations. Adjustable beam levels can be modified to accommodate the dimensions of UK and Euro pallets effectively.

- Double-Deep Racking: Double-deep racking systems provide higher density storage by allowing pallets to be stored two-deep. This configuration can be advantageous for accommodating larger quantities of both UK and Euro pallets.

- Push-Back Racking: Push-back racking systems enable deep-lane storage and offer high-density storage solutions. These systems use carts or rails to store pallets in a Last-In, First-Out (LIFO) manner. By adjusting the lane widths, you can accommodate both UK and Euro pallets efficiently.

- Single size racking: Euro pallets typically can be stored in 1100mm or 700mm deep pallet racking frames. UK standard pallets can be used in 900mm or 1100mm deep pallet racking frames. If you are storing a mixture of Euro and UK standard pallets, an 1100mm deep frame can accommodate both Euro and UK Standard four-way pallets. It is not advisable to stack UK and Euro pallets together.

- 50/50 racking: Racking can be installed to support both types of pallets. This can be achieved by installing different widths of racking for each size of pallet.

Considering Vertical Storage Solutions for Efficient Space Utilization

Maximize your warehouse’s vertical space by considering the following vertical storage solutions:

- Mezzanine Floors: Install mezzanine floors to create additional storage levels above the main floor. These elevated platforms provide valuable space for storing UK and Euro pallets without compromising the existing floor area.

- Stackable Containers: Utilize stackable containers that can be nested when empty to save space. These containers allow you to maximize vertical storage and efficiently manage both types of pallets.

Implementing Proper Pallet Storage Practices

Proper pallet storage practices are essential for maintaining an organized warehouse and ensuring efficient handling of both UK and Euro pallets. In this section, we will explore some best practices to consider when storing and managing pallets in your warehouse.

Segregating UK and Euro Pallets in Designated Storage Areas

To avoid confusion and streamline operations, it’s crucial to segregate UK and Euro pallets in designated storage areas. Clearly mark and label each area to indicate the pallet type it accommodates. This segregation helps prevent pallet mix-ups and allows for easier identification and retrieval when needed.

Assigning specific zones for each pallet type enables efficient inventory management and minimizes the risk of pallet compatibility issues during order fulfilment.

Establishing Clear Labelling and Signage Systems for Easy Identification

Implement a robust labelling and signage system to ensure easy identification of both UK and Euro pallets. Use standardized labels that clearly indicate the pallet type, product details, and any specific handling instructions.

Consider using color-coded labels or signage to further distinguish between UK and Euro pallets. This visual cue helps warehouse staff quickly identify and locate the required pallets, improving efficiency and minimizing errors.

Implementing FIFO (First-In, First-Out) and LIFO (Last-In, First-Out) Practices

To maintain inventory freshness and prevent product spoilage, it’s essential to implement FIFO (First-In, First-Out) and LIFO (Last-In, First-Out) practices.

For perishable goods or products with expiration dates, FIFO ensures that older stock is used first, minimizing waste. LIFO, on the other hand, may be more suitable for non-perishable items or products with a longer shelf life.

By adhering to these practices, you can optimize your warehouse operations and maintain inventory accuracy for both UK and Euro pallets.

Streamlining Pallet Handling and Transportation

Efficient pallet handling and transportation are essential for maintaining smooth warehouse operations when managing both UK and Euro pallets. In this section, we will explore strategies to streamline the movement of pallets within your warehouse.

Standardizing Handling Equipment for Both Pallet Types

To ensure seamless pallet handling, it’s important to standardize the handling equipment used for both UK and Euro pallets. This includes forklifts, pallet jacks, and other material handling equipment.

Investing in versatile equipment that can accommodate both pallet types eliminates the need for separate equipment and reduces complexity in your warehouse operations. Make sure your handling equipment is properly adjusted to safely handle the dimensions and weight capacities of both UK and Euro pallets.

Utilizing Pallet Conversion Solutions

Pallet conversion solutions offer a practical approach to handle both UK and Euro pallets in a single warehouse. These solutions involve using pallet converters or adaptors to modify the dimensions of the pallets temporarily.

By employing pallet converters, you can effectively convert UK pallets to Euro size or vice versa when necessary. This flexibility allows for easier handling and transportation of both pallet types within your warehouse and during distribution processes.

Implementing Efficient Pallet Transportation Processes

Smooth pallet transportation is essential for maintaining a streamlined workflow. Consider the following strategies to enhance pallet transportation efficiency:

- Route Optimization: Plan and optimize the routes for pallet movement within your warehouse. Minimize unnecessary travel distances and eliminate bottlenecks to ensure swift and efficient transportation.

- Dock Management: Implement effective dock management practices to streamline the loading and unloading of both UK and Euro pallets. Clearly define procedures and provide adequate resources to facilitate seamless pallet transfers.

- Collaborative Partnerships: Establish strong relationships with transportation providers who specialize in handling both UK and Euro pallets. Ensure they have the necessary equipment and expertise to handle the specific requirements of each pallet type during distribution.

Maximizing Efficiency with UK and Euro Pallet Management

Effectively managing both UK and Euro pallets in one warehouse can significantly enhance space utilization, operational efficiency, and overall productivity. By following the strategies outlined in this article, warehouse managers can optimize their pallet storage, streamline handling and transportation, and create a well-organized and efficient warehouse environment.

Throughout this article, we discussed the importance of evaluating warehouse space, optimizing racking systems, implementing proper storage practices, and streamlining pallet handling and transportation.

Additionally, considering vertical storage solutions and exploring pallet conversion options further enhance your ability to maximize space and handle different pallet types effectively.

By implementing these best practices and leveraging the expertise of warehouse design professionals, you can transform your warehouse into a well-optimized space that accommodates both UK and Euro pallets with ease.

Expert Warehouse Racking Specialists

At the Rack Group, we specialise in warehouse racking design and storage optimisation services. Our team of experts can assist you in maximizing the efficiency of your warehouse, offering customised solutions tailored to your specific needs.

Start maximising your warehouse space and efficiency and contact us today, and experience the benefits of effectively managing UK and Euro pallets in one warehouse.

Sheffield, UK – 07 11 2023 – Rack Group, a leading provider of warehouse safety solutions, is thrilled to announce the expansion of its international distribution network through a new partnership with Lagerinnredning AS, a prominent Norwegian company specialising in warehouse optimisation and equipment.

Sheffield, UK – 07 11 2023 – Rack Group, a leading provider of warehouse safety solutions, is thrilled to announce the expansion of its international distribution network through a new partnership with Lagerinnredning AS, a prominent Norwegian company specialising in warehouse optimisation and equipment.