optimising warehouse space

Warehouse space is a valuable asset that can significantly impact a company’s bottom line. Maximizing the utilization of this space not only enhances operational efficiency but also helps in cost reduction or even having to not move or expand a warehouse footprint. However, identifying and addressing underutilized areas can be a daunting task. That’s where we come in!

In this blog post, we will provide you with practical insights, expert advice, and proven strategies to help you unlock the hidden potential of your warehouse space. We’ll guide you through the process of reducing underutilized space, ensuring that you have the knowledge and tools to make informed decisions.

Whether you’re a warehouse manager seeking to optimize your storage capacity or a financial manager looking to reduce unnecessary expenses, this blog post is designed to provide you with valuable information and actionable steps to achieve your goals.

Before diving into the process of reducing underutilized warehouse space, it’s crucial to conduct a thorough assessment of your current space utilization. By gaining a clear understanding of how your warehouse space is currently being utilized, you can identify areas of improvement and make informed decisions. Start by examining your inventory and storage patterns. Take stock of the types of products you store, their demand levels, and their storage requirements. Identify any discrepancies between inventory levels and storage capacity. This analysis will help you identify areas where space is being underutilized or overutilized.

Evaluate Space Allocation

Assess how your warehouse space is currently allocated and utilized. Measure the actual space occupied by various storage systems, equipment, aisles, and other infrastructure components. Compare this with the planned or designated space. Identify areas where space is underutilized, such as wide aisles, empty racks, or unused corners.

Utilize Data and Metrics

Leverage data and metrics to quantify the extent of underutilization and measure the effectiveness of your space utilization efforts. Key metrics to consider include storage capacity utilization, inventory turnover rates, and storage density. Analyzing these metrics will provide insights into the areas that require attention.

Engage Warehouse Staff

Involve your warehouse staff in the assessment process. They possess valuable first hand knowledge and insights about the warehouse’s day to day operations. Conduct interviews or surveys to gather their input on areas of potential improvement and underutilization.

By conducting a comprehensive assessment of your warehouse’s space utilization, you lay the foundation for effective optimization. Identifying underutilized areas and understanding the factors contributing to low utilization enables you to make targeted improvements.

Optimizing Warehouse Layout and Organization

A well-optimized warehouse layout and organization play a pivotal role in maximizing space utilization. By strategically arranging your storage systems and streamlining workflows, you can make the most of every square foot in your warehouse. Let’s explore some effective strategies for optimizing your warehouse layout and organization.

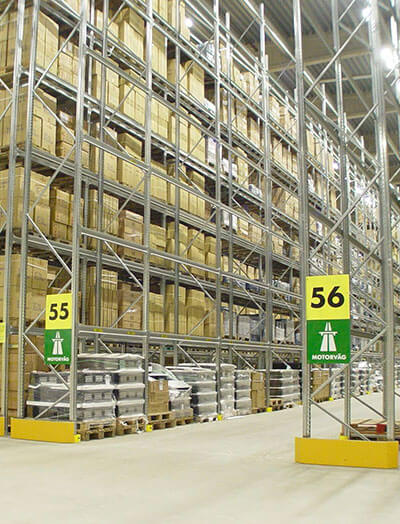

- Reevaluate Racking Systems: Start by reassessing your racking systems. Consider implementing space-saving solutions such as narrow aisle racking or high-density storage systems like push-back or drive-in racks. These systems maximize vertical space utilization and allow for tighter aisle configurations.

- Embrace Vertical Space: Make use of vertical space by installing mezzanine levels or double-decker storage systems. These additions increase your storage capacity without expanding your warehouse’s footprint. Utilize stackable containers or bins to efficiently store goods and create vertical storage columns.

- Implement Efficient Slotting Techniques: Optimize your slotting strategy by analyzing product characteristics, demand patterns, and picking frequencies. Categorize your products based on their storage requirements and pick frequencies to assign them to the most appropriate locations. This reduces unnecessary travel time and increases efficiency.

- Utilize Mobile Shelving Systems: Mobile shelving systems are an excellent solution for warehouses with limited space. These systems use movable racks that compact together, creating additional aisle space when not in use. By maximizing aisle space, you can allocate more room for storage.

- Consider Cross-Docking Operations: Cross-docking is a technique that allows goods to be transferred directly from inbound to outbound vehicles with minimal or no storage time. By eliminating the need for traditional storage, cross-docking reduces space requirements and expedites order fulfilment.

By revaluating your racking systems, embracing vertical space, implementing efficient slotting techniques, utilizing mobile shelving systems, and considering cross-docking operations, you can optimize your warehouse layout and organization to reduce underutilized space.

Maximizing Inventory Management Efficiency

Efficient inventory management is key to reducing underutilized warehouse space. By implementing effective inventory control measures and adopting smart strategies, you can optimize inventory levels and storage space utilization. Let’s delve into strategies for maximizing inventory management efficiency.

- Conduct ABC Analysis: Perform an ABC analysis to categorize your inventory based on its value and demand. Classify items as A (high-value, high-demand), B (moderate-value, moderate-demand), and C (low-value, low-demand). This analysis helps prioritize storage space allocation and inventory control efforts.

- Implement Just-in-Time (JIT) Inventory Management: Just-in-Time inventory management focuses on minimizing excess inventory by receiving goods as they are needed for production or order fulfillment. This approach reduces storage needs, lowers carrying costs, and ensures efficient utilization of warehouse space.

- Optimize Reorder Points and Order Quantities: Fine-tune your reorder points and order quantities to align with demand patterns and lead times. By accurately forecasting demand and adjusting reorder points, you can avoid overstocking or stockouts, thereby optimizing storage space utilization.

- Implement Cycle Counting: Instead of relying solely on time-consuming and disruptive physical inventory counts, consider implementing cycle counting. Cycle counting involves regularly counting a small portion of your inventory on an ongoing basis. This approach provides accurate inventory visibility and helps identify and rectify discrepancies promptly.

- Leverage Technology: Leverage inventory management software and warehouse management systems (WMS) to gain real-time visibility into your inventory levels, locations, and movements. These technological tools enable efficient inventory tracking, order fulfilment, and space optimization.

Embracing Automation and Technology

In today’s fast-paced world, embracing automation and technology is crucial for efficient warehouse operations and space utilization. By leveraging advanced systems and tools, you can enhance productivity, accuracy, and space optimization. Let’s delve into the benefits of embracing automation and technology in warehouse optimization.

- Automated Storage and Retrieval Systems (AS/RS): AS/RS systems are robotic systems that automate the storage and retrieval of goods. These systems utilize advanced technologies such as automated conveyors, cranes, and robots to efficiently move and store inventory. By maximizing vertical space utilization and reducing manual handling, AS/RS systems can significantly optimize warehouse space.

- Pick-to-Light and Put-to-Light Systems: Pick-to-Light and Put-to-Light systems use visual indicators to guide warehouse personnel during order picking and put-away processes. These systems improve accuracy, reduce errors, and enhance productivity. By minimizing travel time and optimizing pick paths, they contribute to efficient space utilization.

- Warehouse Management Systems (WMS): A robust WMS is essential for effective warehouse management. These software platforms provide real-time visibility into inventory, order processing, and space utilization. By automating tasks such as inventory tracking, order routing, and space optimization, WMS significantly enhances warehouse efficiency.

- Internet of Things (IoT) Sensors: IoT sensors can be installed throughout the warehouse to monitor and collect data on various parameters such as space utilization, temperature, humidity, and equipment performance. By analysing this data, you can identify bottlenecks, optimize workflows, and make data-driven decisions to maximize space utilization.

- Warehouse Visualization and Simulation Tools: Utilize warehouse visualization and simulation tools to model and analyse different layout configurations. These tools provide a visual representation of your warehouse and simulate the impact of layout changes on space utilization. By experimenting with various scenarios, you can make informed decisions about optimizing your warehouse layout.

By embracing automation and technology, you can revolutionize your warehouse operations and achieve maximum space utilization.

Summary and Key Takeaways

In this article, we’ve explored various strategies and techniques to reduce underutilized warehouse space or repurpose space. By implementing these strategies, warehouse to financial managers can start to optimize space utilization, increase operational efficiency, and maximize their return on investment.

Warehouse Racking Specialists

We know that every warehouse is unique, so it’s essential to assess your specific needs and tailor the strategies accordingly. Contact our team of experts today to discuss your warehouse optimization needs and explore how our solutions can transform your space utilization. Let’s embark on the path to warehouse efficiency together!

Sheffield, UK – 07 11 2023 – Rack Group, a leading provider of warehouse safety solutions, is thrilled to announce the expansion of its international distribution network through a new partnership with Lagerinnredning AS, a prominent Norwegian company specialising in warehouse optimisation and equipment.

Sheffield, UK – 07 11 2023 – Rack Group, a leading provider of warehouse safety solutions, is thrilled to announce the expansion of its international distribution network through a new partnership with Lagerinnredning AS, a prominent Norwegian company specialising in warehouse optimisation and equipment.