If you run a business that utilises a warehouse as its operational hub, you understand the importance of efficiently utilising the available space.

Whether it’s maximising storage capacity or creating new work areas, there are numerous strategies to optimise the square footage of your warehouse. An effective solution worth considering is the installation of a mezzanine floor—a raised platform that offers additional floor space within your warehouse. This blog post will delve into the various types of mezzanines that exist and provide guidance on selecting the most suitable one for your business.

Benefits of Mezzanine Flooring

Mezzanine installations offer numerous benefits for warehouses of all sizes and industries. Here are some of the key advantages of adding a mezzanine to your warehouse:

Increased Storage Capacity and Flexibility

One of the most significant benefits of mezzanine installations is the extra storage space they provide. Mezzanines can be used to store products, equipment, and supplies, allowing you to make the most of your vertical space. This increased storage capacity also gives you more flexibility in organizing your warehouse, enabling you to optimise your workflow and increase productivity.

Improved Organisation and Accessibility

Mezzanines can help you organize your warehouse more efficiently. By using the extra space to store products and equipment, you can create more accessible pathways and workspaces, reducing the time it takes to locate and retrieve items. This improved organization can help you improve your workflow and productivity, reducing errors and increasing accuracy.

Creation of New Workspace and Repurposing of Existing Space

Mezzanine installations can also create a new workspace and allow you to repurpose existing space. If your warehouse is running out of floor space, a mezzanine installation can provide an additional level for offices, break rooms, or other workspace. Additionally, a mezzanine can help you repurpose existing space by allowing you to move storage or equipment to the upper level, freeing up floor space for other purposes.

Increased Property Value

Finally, mezzanine installations can increase the value of your property. By adding a mezzanine, you’re essentially creating additional square footage, which can increase the overall value of your warehouse. If you’re looking to sell or lease your property in the future, a mezzanine installation can help you attract more buyers or tenants and increase your return on investment.

Types of Mezzanine Installations

When it comes to selecting a mezzanine installation for your warehouse, there are numerous options to choose from. Here are just some of the most common types of mezzanine installations:

- Free-Standing Mezzanines are self-supporting structures that don’t require any additional support from the building’s existing structure. These mezzanines can be easily relocated or expanded and are ideal for warehouses with high ceilings.

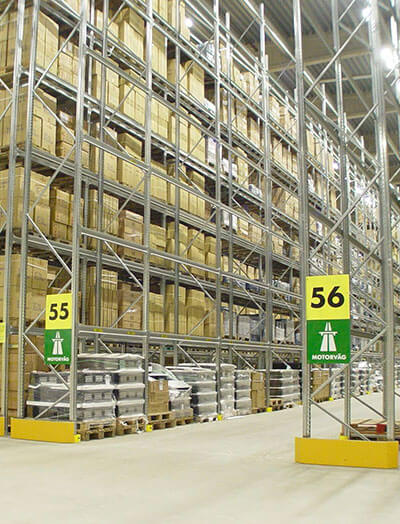

- Rack-Supported Mezzanines use existing pallet racking as the support structure for the mezzanine platform. This option is ideal for warehouses with limited floor space or those looking to add storage space above their existing pallet racking.

- Shelving-supported mezzanines use existing shelving units as the support structure for the mezzanine platform. This option is ideal for warehouses with limited floor space or those looking to add storage space above their existing shelving units.

- Structural steel mezzanines are designed to support heavy loads and are ideal for warehouses that need to store large or heavy equipment or machinery. These mezzanines can be custom designed to fit your specific needs and can be used for storage, production, or office space.

Installation and Maintenance

Once you’ve decided you need a mezzanine for your warehouse, it’s important to ensure that it’s installed and maintained properly. Here are some key things to consider:

- Design and installation

It’s important to work with a professional mezzanine design and installation company that will consult and advise on the optimum solution for your workplace. This will include not only the best design but is in the best location, good access and a cost-effective solution. A company will also ensure that your mezzanine meets all regulatory requirements and building codes. - Regular Maintenance

It is essential to ensure that your mezzanine stays in good condition and continues to operate safely. Make sure to schedule regular inspections and maintenance with your mezzanine installation company. - Safety Features

Make sure that your mezzanine installation includes all necessary safety features, such as guardrails, handrails, and safety gates. These features will help prevent accidents and injuries in your warehouse. - Employee Training

Make sure that all employees who will be working on or around the mezzanine receive proper training on how to use it safely. This includes training on how to access the mezzanine, how to load and unload materials, and how to use any safety features.

If you’re considering installing a mezzanine in your warehouse, make sure to work with a reputable and experienced mezzanine installation company that can provide not only professional installation and maintenance services but also guidance on safety, regulations and compliance.

To learn more about the different types of mezzanine installations and which option is best for your warehouse, schedule a consultation with our experts.