Warehouse racking safety is not optional. Damaged pallet racking is one of the leading causes of serious warehouse accidents, stock loss and costly downtime. Yet many sites still rely on visual checks with no proper measuring tools, reporting system or inspection structure.

If you are responsible for warehouse safety, compliance or operations, having the right racking inspection kit is essential.

In this guide, we explain what makes a good racking inspection kit, the most common racking issues we see every day, and why the Rack Group Racking Inspection Kit is trusted by warehouse teams across the UK.

Why Racking Inspections Are Critical for Warehouse Safety

Pallet racking systems are constantly exposed to demanding conditions that compromise their structural integrity over time.

Common sources of racking stress include:

- Forklift impacts

- Heavy loads

- Daily traffic

- Poor loading practices

- General wear and tear

Over time, even small knocks can weaken uprights, distort frames and compromise structural integrity. Left unchecked, minor damage can quickly turn into a major collapse risk.

Regular inspections help you:

- Prevent serious accidents

- Reduce downtime and stock loss

- Stay compliant with safety legislation

- Extend the life of your racking

- Protect your workforce

If you would prefer a qualified inspector to carry out a formal assessment, you can book support through our Racking Inspections service.

Key Takeaways

- Damaged racking is a leading cause of warehouse accidents and costly downtime

- Regular inspections with proper measuring tools help prevent serious collapse risks

- The Rack Group Racking Inspection Kit includes everything needed for compliant weekly checks

- A structured inspection process protects your workforce and extends racking lifespan

The Most Common Racking Damage We See

Rack Group has over 25 years’ experience supplying warehouse storage solutions across the UK. Our team designs, installs, repairs and inspects pallet racking every day, so we understand exactly where damage occurs and how to prevent costly failures. You can learn more about our background on our About Us page.

Common Racking Damage Types

- Forklift impact damage to uprights

- Bent or twisted frames

- Dislodged or missing beams

- Incorrect beam levels

- Overloaded bays

- Missing safety pins

- Floor fixings pulled out

These issues are often invisible at first glance. That is why accurate measuring, checking and reporting is essential.

What Makes the Best Racking Inspection Kit

A professional racking inspection kit should allow your team to carry out thorough, compliant inspections with confidence.

| Essential Feature | Why It Matters |

|---|---|

| Accurate measuring tools | Identify damage severity to safety standards |

| Level checking equipment | Detect misalignment and structural issues |

| Damage reporting system | Maintain compliance and track repairs |

| Tagging materials | Isolate unsafe bays immediately |

| Portable carry case | Easy transport around large warehouses |

Anything less than a complete, professional kit is guesswork, and guesswork has no place in warehouse safety.

The Rack Group Racking Inspection Kit

We supply our own Rack Group Racking Inspection Kit, designed specifically for warehouse and logistics environments. It includes everything required to carry out compliant racking inspections.

Buy the Rack Group Racking Inspection Kit here: https://therackgroup.com/product/racking-inspection-kit/

Protect Your Warehouse Today

Get everything you need for compliant racking inspections in one professional kit.

What Is Included

Each Rack Group Racking Inspection Kit includes:

- 1m ruler with spirit level

- Small ruler

- Wooden measuring wedge

- Tape measure

- String line

- LED torch

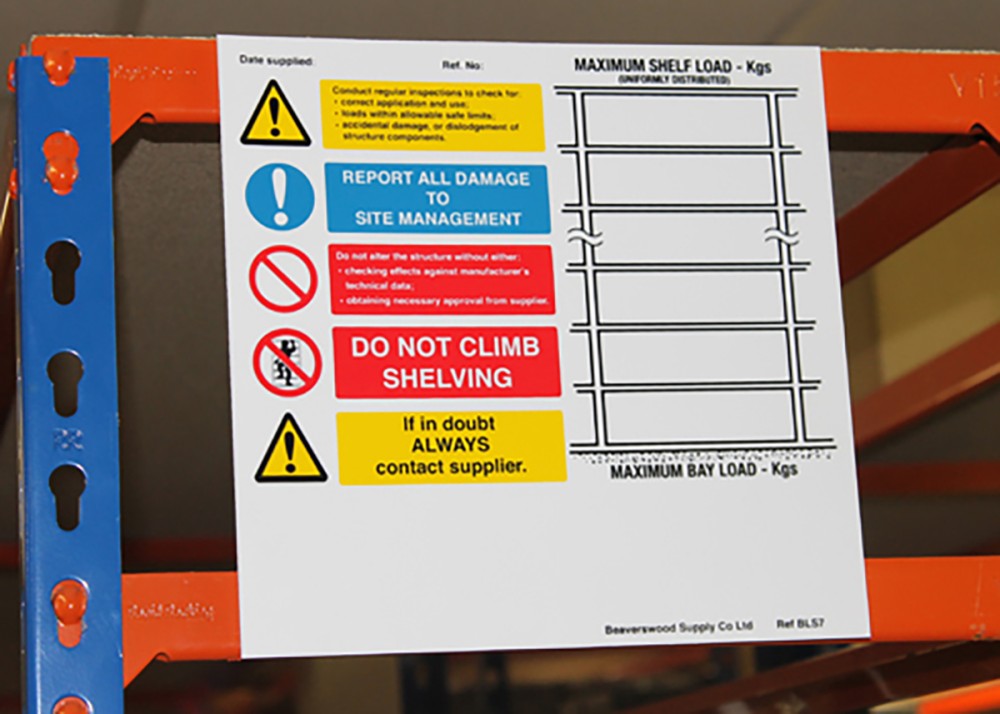

- Sample damage report tags

- Free damage report book

- Heavy duty carry case

Every tool is included to help identify, measure and record racking damage correctly.

Order Your Inspection Kit Now

Start protecting your warehouse with the right tools and processes.

Recommended Weekly Racking Inspection Process

We recommend a simple, structured weekly inspection process that takes the guesswork out of warehouse safety.

Weekly Inspection Checklist

- Walk every aisle

- Check uprights for impact damage

- Measure any bends or twists

- Check beams are seated correctly

- Confirm safety locks are fitted

- Inspect floor fixings

- Tag any damaged areas

- Log findings in the report book

- Arrange repair immediately

For any damage that needs professional action, our Racking Repairs service can help you return the system to a safe, compliant condition.

Compliance with Safety Regulations

Our inspection kit is designed to help warehouses comply with UK and international safety standards.

Compliance Standards Supported

- HSE (UK Health and Safety Executive)

- PUWER Regulations

- SEMA Guidelines

- EN 15635 European Standard

- OSHA best practice for international sites

It supports both internal weekly checks and formal annual inspections. If you need an expert-led inspection programme, our Racking Inspections service covers nationwide sites and supports ongoing compliance.

Common Racking Safety Mistakes Warehouses Make

Even well-intentioned warehouse teams can fall into dangerous safety gaps without the right tools and processes.

Mistakes to Avoid

- Not inspecting racking regularly

- Ignoring minor impact damage

- Not measuring bends correctly

- No damage reporting system

- No tagging of unsafe bays

- Leaving damaged racking in service

Our kit provides:

- The correct measuring tools

- Clear damage reporting

- Visual tagging

- A structured inspection process

This removes guesswork and helps ensure full compliance.

Training, Support and Ongoing Compliance

Rack Group supports warehouse safety end to end. Alongside the inspection kit, we provide:

- On-site racking inspections

- Repair services

- Annual inspections

- Inspection templates

- Damage report books

- Ongoing support from our technical team

- Training for warehouse staff on weekly inspections

If you want to upskill your team so they can carry out weekly checks correctly, explore our Pallet Racking Safety Courses.

Buy the Rack Group Racking Inspection Kit

If you are serious about warehouse safety, compliance and accident prevention, our kit provides everything your team needs in one simple package.

Buy now: Rack Group Racking Inspection Kit

Invest in Warehouse Safety Today

Get the complete inspection solution trusted by warehouse teams across the UK.

Frequently Asked Questions

How often should racking be inspected?

Weekly inspections should be carried out by trained warehouse staff using a racking inspection kit. Annual inspections must be completed by a competent inspector to support ongoing compliance with safety guidance.

What damage requires immediate action?

Dislodged beams, missing safety pins, pulled floor fixings, or any damage that compromises stability should be tagged, isolated from use, and repaired as soon as possible.

Can I carry out racking inspections myself?

Yes. Weekly inspections can be carried out by trained internal staff using the proper tools and reporting systems. Many sites also arrange formal inspections periodically through a specialist provider.

What should I do if I find damage during an inspection?

Tag the damaged bay immediately using damage report tags, record the findings in your inspection report book, isolate the area from use, and arrange professional repair as soon as possible. Never leave damaged racking in service.

Does the kit include training materials?

The kit includes sample damage report tags and a free damage report book to support your inspection process. For comprehensive staff training on how to carry out weekly inspections correctly, we recommend our Pallet Racking Safety Courses.

Is the kit suitable for all types of pallet racking?

Yes. The Rack Group Racking Inspection Kit is designed for use with standard pallet racking systems across warehouse and logistics environments.

Final Thoughts

A racking collapse can cost hundreds of thousands in lost stock, insurance claims, downtime and injuries. Regular inspections using the right tools are one of the simplest and most effective safety investments any warehouse can make.

With over 25 years of hands-on industry experience, Rack Group has designed a kit that works in real warehouses and supports a structured inspection routine.

If you want safer racking, fewer incidents and full compliance, start with the right inspection kit and build a consistent inspection process around it.

In conclusion, mitigating the risk of racking collapse is a multi-faceted approach that relies on professional installation, regular maintenance, and diligent inspections. Equally important is providing thorough training to warehouse teams to recognise potential hazards and respond swiftly to ensure a safe, secure workplace. By implementing these strategies, warehouse managers can proactively protect their facility, personnel, and valuable inventory from the threat of racking failures.

In conclusion, mitigating the risk of racking collapse is a multi-faceted approach that relies on professional installation, regular maintenance, and diligent inspections. Equally important is providing thorough training to warehouse teams to recognise potential hazards and respond swiftly to ensure a safe, secure workplace. By implementing these strategies, warehouse managers can proactively protect their facility, personnel, and valuable inventory from the threat of racking failures.