Rack Armour® returns to ProMat as the world’s leading impact protection for racking uprights, with a new USA range of industrial products, already used widely across Europe.

Rack Armour®, from its location on Stand N6636, will return to ProMAT to display innovative products and solutions for the logistics, material handling, and industrial sectors across the USA. These range from impact protection of racking and storage systems to warehouse recycling solutions, labelling, visual management signage, and more.

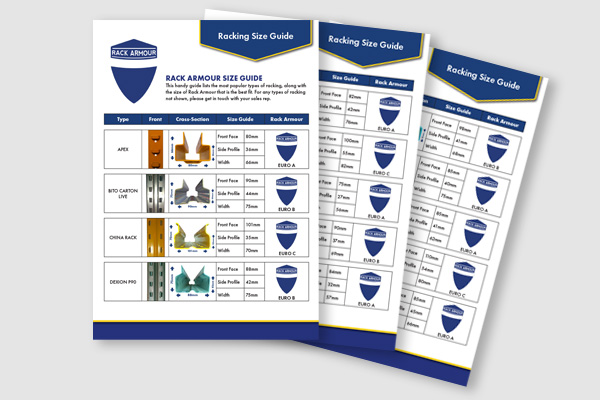

Along with Lean Inc, USA master distributor, Rack Armour® will exhibit the world’s best-selling upright protection solution which guarantees an 80% reduction in racking damage. Made from ballistics grade plastic, the outer shell of Rack Armour® is shaped to divert impact energy around the rack leg instead of through it. Any remaining impact energy is absorbed by the interior foam until it’s diffused. This twin action protection uniquely helps maintain the structural integrity of the racking system – which saves tens of thousands of pounds in damage repair costs. Lean Inc will be happy to discuss USA reseller opportunities for this fantastic product which provides an 800% proven customer ROI.

Beaverswood®, a leading manufacturer of visual management and recycling solutions, will be on hand to showcase its latest products to potential USA resellers, such as the award-winning racksack® mini. Available in many sizes, this waste segregation solution is perfect for shelving, smaller racking areas, and workbenches, picking stations, desks, and more. Additionally, Modulean® rack end shadow boards, an innovative way to transform redundant end-of-aisle racking space into working space, will be displayed. All of this, plus Beaverswood®’s well-known offering of high-quality warehouse labels, aisle and bay markers, document display, and floor marking, will be on show.

Rack Armour® and Beaverswood® are part of IWS Group, a group of industry-leading companies, cutting-edge in their own fields of expertise, while working collaboratively to provide outstanding services and solutions in the industrial workplace. Lean Inc is the master distributor in the USA and is actively looking to onboard more distributors across the USA for both Rack Armour® and Beaverswood®. We will have several representatives from Lean Inc, Rack Armour®, and Beaverswood® on our stand, ready to explain how these innovative products can best support your organisation.